|

|||||||

| GT2, GT3, RS and Cup Car Discussions Discussions on all topics related to all Porsche GT vehicles |

|

|

Thread Tools | Search this Thread | Display Modes |

|

#1

|

||||

|

||||

|

While many are scrambling to find an RS 4.0 allocation, we are taking a different approach. Allow me to introduce the IPB-Autosport 4 liter project.

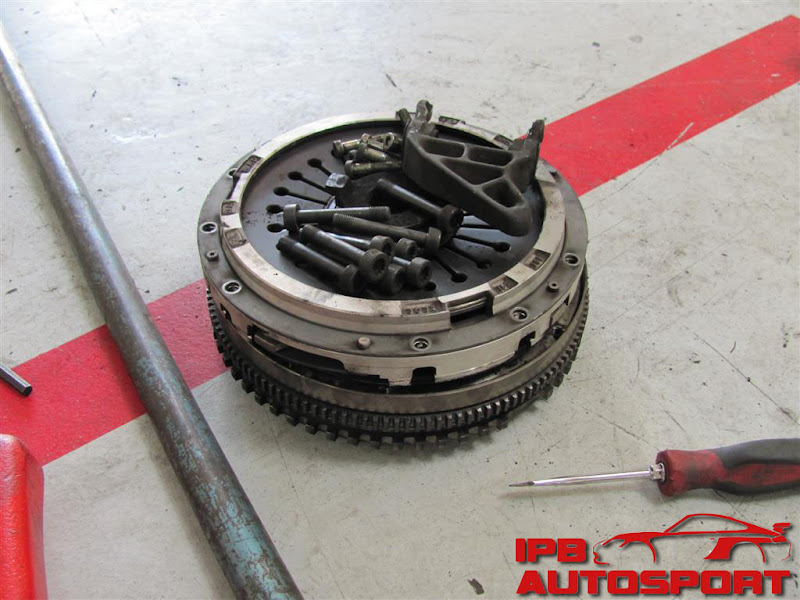

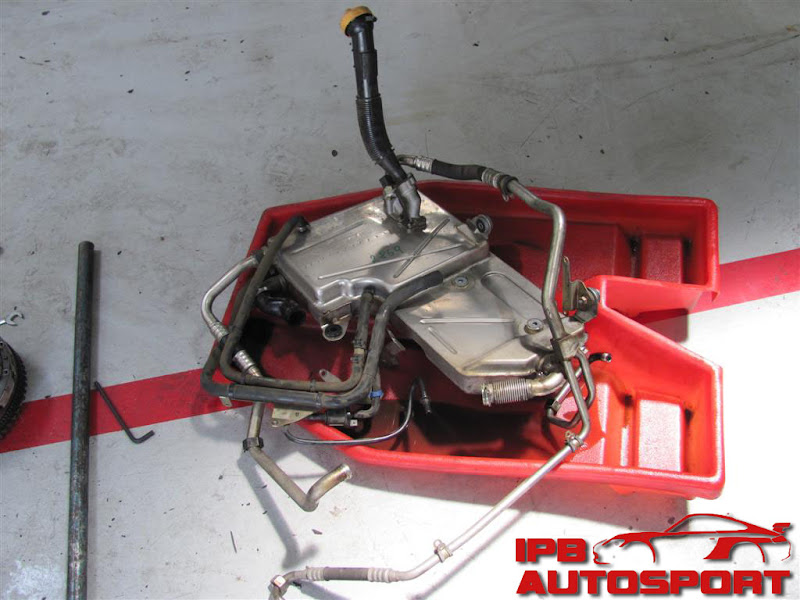

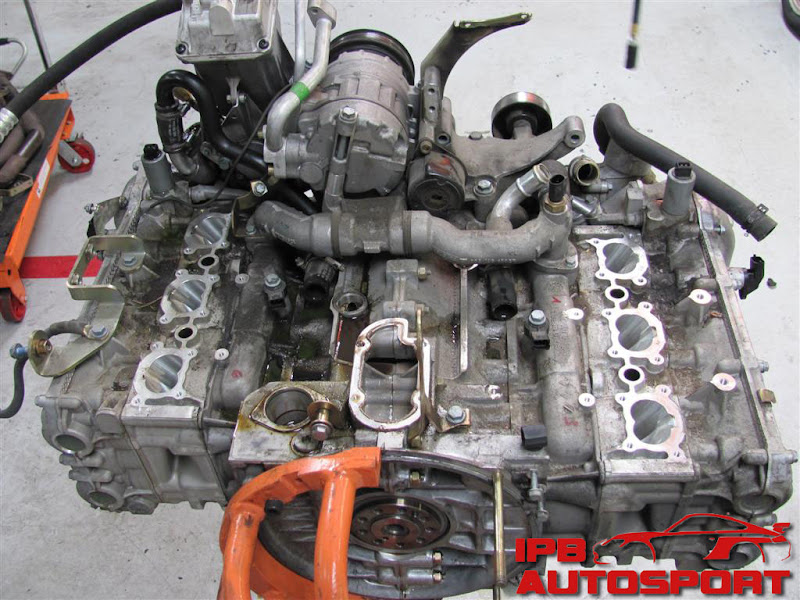

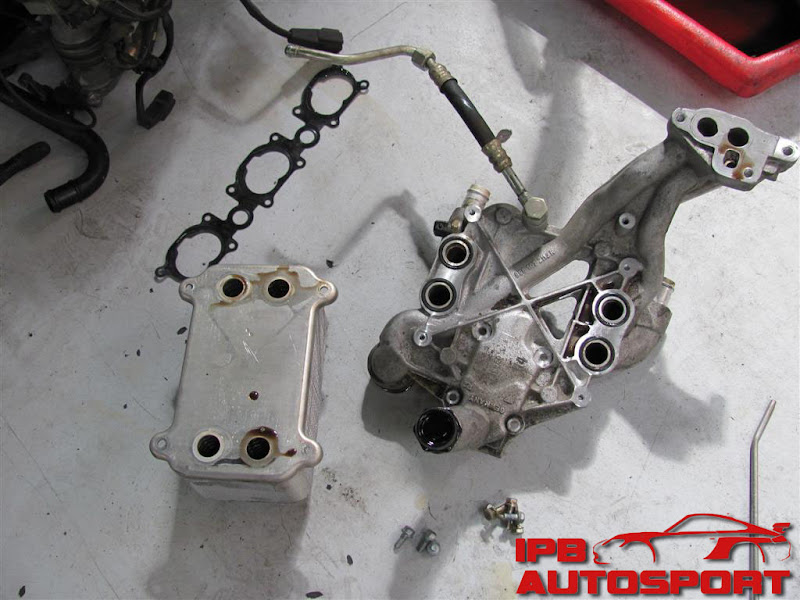

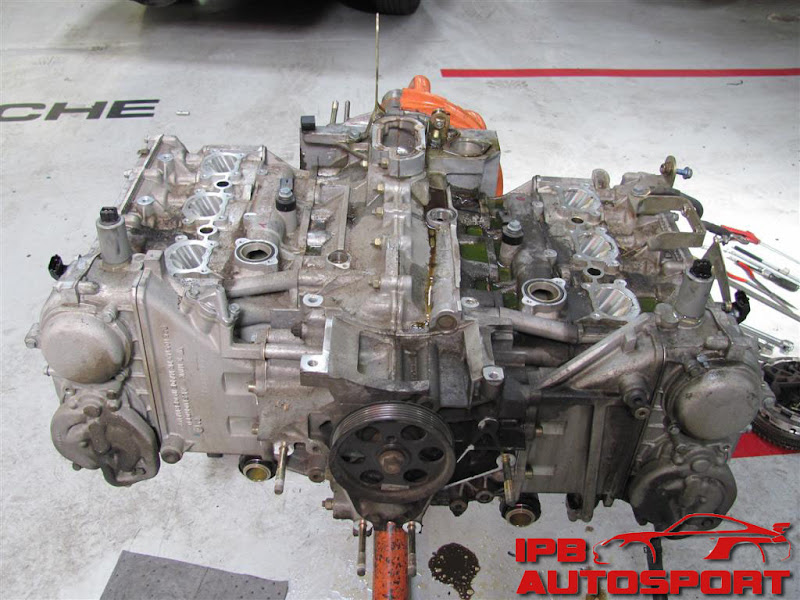

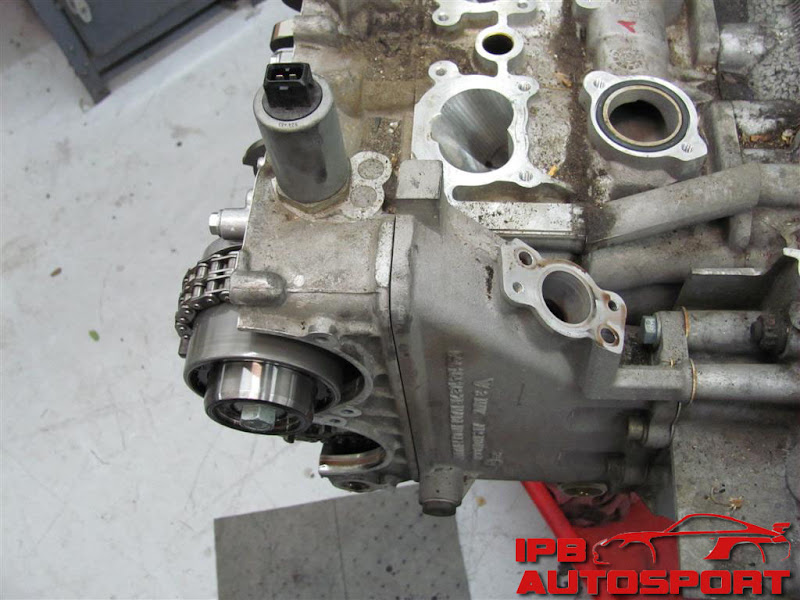

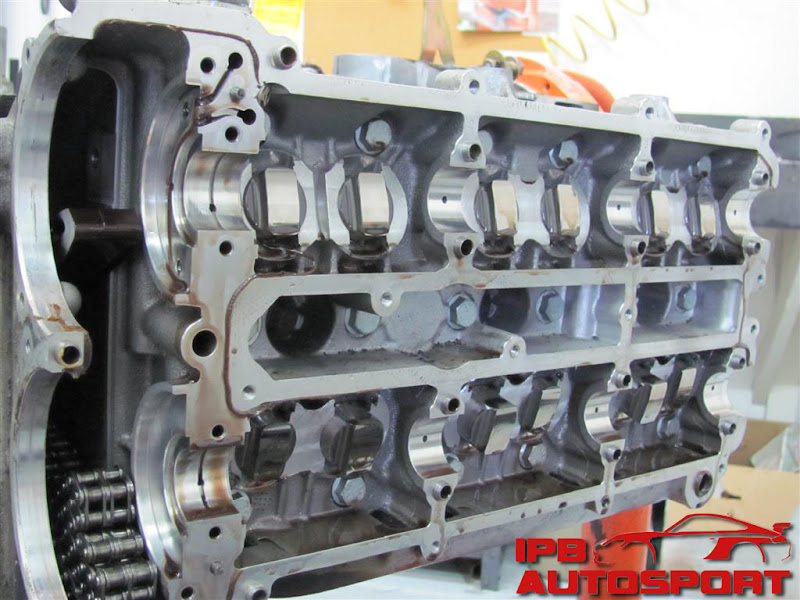

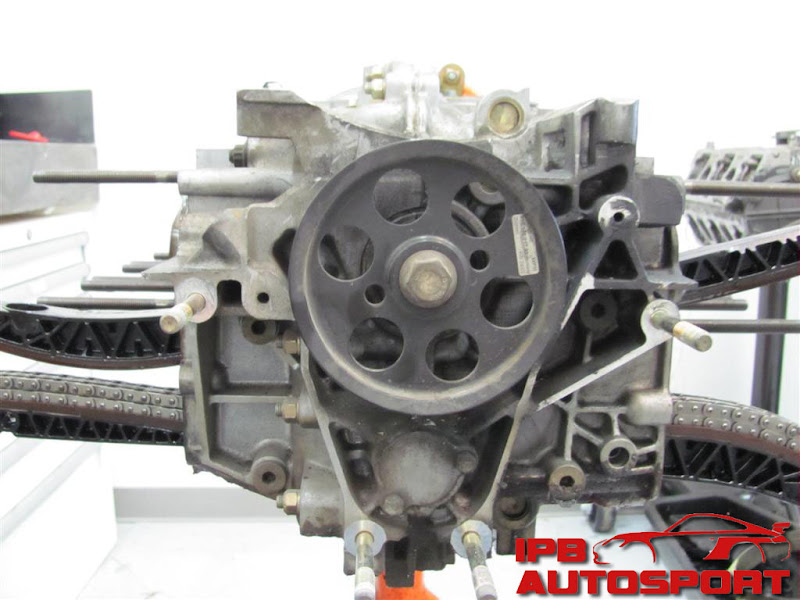

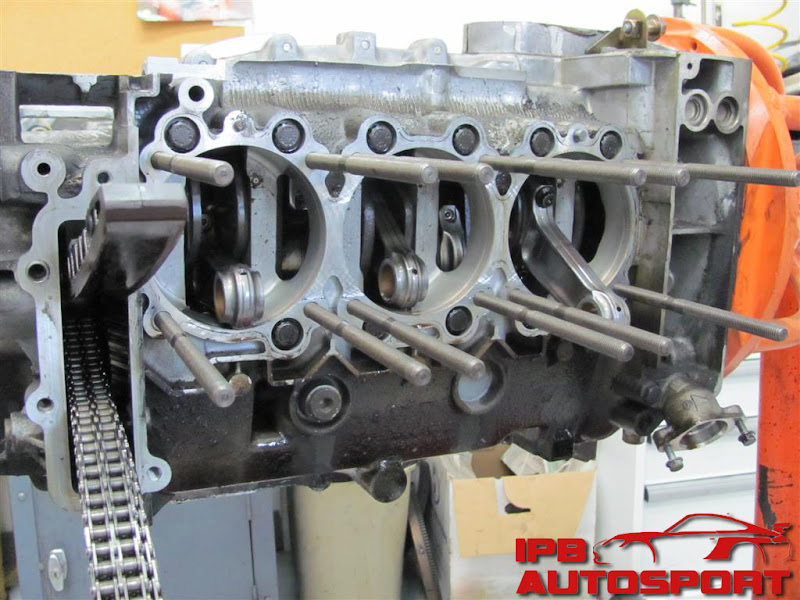

First things first, the engine has to come out. After removing the airbox, draining and disconnecting the coolant system, evacuating the A/C, disconnecting power steering lines, fuel lines, engine harness, misc vacuum lines, etc, the car goes up in the air.  Once the plastic underbody panels are removed, we gain access to everything else that has to be disconnected: axles, cross members, sway bar, starter, ground, transmission cables, clutch slave, additional coolant lines including the tranny cooler, and of course engine/transmission mounts. The whole unit drops out.  It’s massive.  The engine and transmission is split and the clutch is removed. Stock flywheel isn’t light. An RS LWFW will be taking its place.  Clutch plate still looks good.  Two studs are pulled and the engine is secured with allens.   Out comes the oil tank and associated lines.   Next the intake manifold.     Oil cooler and cooling manifold come out.   Alternator and A/C compressor comes next.  Power steering pump and reservoir.  Water pump comes out last.  We are down to a long block.  All the parts are stashed on a cart, and the transmission sits nearby. Once the case is split and sent off to machining, the differential will be pulled and rebuilt with Guard internals.  In the engine room is a freshly rebuild air cooled engine waiting to go into a genuine 914-6. Numerous flat-6 engine parts everywhere – accumulated through years of engine building experience.  My engine is next to a 993 GT2 Evo 3.8. Cool, huh?  We need more motivation in this room. Ah yes, the Wurth calendar!  Cam covers come off with the motivation of big orange.   Out come the chain tensioners.  Porsche specialty tools are used to hold the cam gears in order to loosen the nuts.  Lifters are now exposed. These are placed into a labeled bin so that they can be reused in the same locations.  Timing chain housings and cam housings come out.  Then the heads.  Parts lay on the work table.   Cylinders slide off exposing the pistons.   Pistons are unclipped.   Time to split the case.  The engine stand is struck with a hammer to shock the case.   The internals are beautiful.  That's all for tonight - the past few days have been exhausting! |

|

|